What do we need for Artificial intelligence?

Our blogsOm AI in het productieproces te implementeren, moet er aan een aantal dingen worden voldaan. Which ones they are, you will read in this article.

10 reasons why an MES implementation may be delayed

News, Our blogsAt Greywise, we assist manufacturing companies with implementing MOMS solutions, including, of course, MES (Manufacturing Execution System). One of our main concerns is to avoid unnecessary delays.

IT and OT: How can you bridge the gap?

News, Our blogsTo bridge the gap between IT and OT, start by creating a plan, with what is written in the introduction as the main input!

IT and OT in the industry: Ensure separation & collaboration

Our blogsIn summary, you can say that the speed of change within IT is much higher and that OT is still very unknown within IT. OT cannot change as quickly as IT and the OT landscape becomes fragmented as a result, so that you can disrupt the production process with updates. Certainly without good insight into the application and systems landscape, the impact cannot be predicted.

MES in practice: “The importance of management processes is often underestimated”

Our blogs, UncategorizedThe importance of good management processes for Manufacturing Execution Systems, or MES for short, is often underestimated. I've seen several situations where that led to problems. In a MES project a few years ago, I saw the complexity of the process and software increase and therefore the number of bugs. You then have teething problems for a longer period after the system has been handed over to the organization. This could have been prevented with a good management process.

The difference between IT and OT

Our blogs, UncategorizedThe difference between IT and OT is best explained with different levels of automation. The IT and OT domains each span different levels and have their own focus areas and priorities. The different levels of automation are best explained using the Purdue model

What is an Electronic Batch Record?

Our blogs, UncategorizedPharmaceutical companies are required to maintain batch records so that authorities can confirm proper procedures are being followed. Modern Electronic Batch Records (EBR) can help with this and help companies comply with FDA regulations. An electronic batch record uses several databases that record data that is recorded during the production of a batch. In addition, it uses a business process engine that defines the process to be followed.

What is GAMP5 (GAMP®5)?

Our blogs, UncategorizedGAMP5 (GAMP®5), or 'Good Automated Manufacturing Practices' is a non-mandatory legislation for pharmaceutical and food companies. It provides important guidelines for companies involved in the development and/or implementation of automated systems.

Data-driven manufacturing: “Manufacturing companies often do not realize the importance of data”

Our blogs, UncategorizedMany production organizations have invested in lean manufacturing, which has resulted in attractive profits. However, there is still much to be gained in the field of data, especially master data...

MES in the ‘food’: What is Manufacturing Execution System and what do you need to know about it?

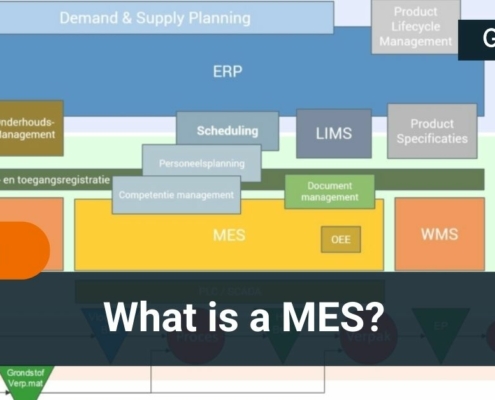

Our blogs, UncategorizedA Manufacturing Execution System (MES) enables the exchange of information between the shop floor (machinery, but also people) and the office environment (ERP)...

Start on time with a MES and get a head start on your competition

Our blogs, UncategorizedA Manufacturing Execution System (MES) is often started too late. This is a shame and causes much more hassle and costs!

Why MES can be of great added value right now!

Our blogs, UncategorizedOf course, as an employer you want the best for your staff and you want to comply with legal requirements – but production also needs to continue and in the most efficient way. MES can play a major, and not to be underestimated, role in the workplace and the departments above.

MOM vs MES: Operation Management vs Execution System

Our blogs, UncategorizedYou hear the term MOM more and more often and this usually in combination with MES. But is there actually a difference between MES and MOM? In this article we provide the answer to this question.

Which MES providers are there in the Netherlands & Belgium?

Our blogsThere are different types of MES systems and all these systems have their unique properties. But which system suits your type of organization well?

What is a Manufacturing Execution System (MES)?

Our blogs, UncategorizedA Manufacturing Execution System (MES) enables information exchange between production (people and machines on the shop floor) and the office environment (ERP). The Manufacturing Execution System (MES) receives the orders from the ERP system and ensures that the various production departments are provided with the correct information. This information is collected in the MES and made available to the ERP system.